Akira Akatsuka

Other than eyeglasses, we also make accessaries.

Studio

About Taimai (hawksbill turtle)

Tortoise shell in Edo Period

Materials such as an elephant tusk never deteriorate and it even gets its luster as they are used. Also, the name of the craver would worth with the name carved on the product. On the other hand, works of tortoise shell basically do not have their artist. Tortoise shell is at its best quality when its first made into a product and after, it only deteriorates. This is thought to be one of the good things about tortoise shells.

How did Akatsuka become a tortoiseshell craftsman?

Could you tell me why you became a tortoiseshell craftsman?

Edo-style Tortoiseshell crafts

About Edo-style Tortoiseshell crafts?

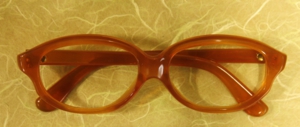

Basically, I make eyeglasses that had been made from my previous generations. I often do repairs too.

Are there any differences between the goods from Edo and other areas?

There is none right now. There could have been in the past. In the Edo period, the areas that were manufacturing the tortoise shell products were what would now be called Tokyo, Nagasaki, and Osaka. There were these top three producing areas then, and in Nagasaki, people made products that foreign people purchase for souvenirs. They say boxes, but there seems to be many jewel boxes, inkstone cases, and other ornaments. In Tokyo, they made hairpins and glasses for oiran. In the case of Osaka, we do not know very much, but they make combs today, the ones that barbers use. Probably, because Osaka has a port, they could have transported materials from Nagasaki back then. There are still few doors in Osaka, but compared to the past, the numbers has gotten low.

Could you tell me about the production process?

In the case of eyeglasses, you would have to first make a pattern, which is called “tama-gata”. According to the size the dealer sends, we make the pattern from a plastic sheet, and then the nose and the side part. In addition, the top and the bottom part from a straight stick. Then after, we cut the material, which is fixed to the pattern with a fret saw. The thickness may vary, so we put some parts together to make it to the thickness that we want. To bond the parts together, water, heat, and pressure is used, and never a glue. Put it between plates and press. Before connecting them, we see the texture. We hold the material up to the light and see which parts to take. It is very important to not make waste when cutting it out.

The arm is cut in the middle, but I never use a fret saw here. A loss is always produced when a fret saw is used. On the other hand, a dinking does not. However, it is very difficult to keep cutting the center. There are always some possibilities that it might get twisted, when too much power is put in the process, but If you get used to it, this is the best way. Then, we adjust the thickness. After, we use fine sand cloth to polish the surface and warm it to bend so that it fits the ears. We also use motor rollers to polish. We first do clay polishing and then to give luster, we do the finishing polishing.

Could you tell me which process requires skills?

I guess the first process of deciding which materials to choose and how to match them. It’s all about his sense. This process makes up the last quality of the work. The process after that is flow process, so not much difference could be made no matter whomever was in charge. The finished product look like this, but the first process is always different. Even if it was the combination of three plates before, I would have to fix five this time, or four, it is always different patterns. It is very difficult to use different materials and make it to same products.

Could you tell me if adjusting the thickness is difficult?

Yes, but what is more, is the color. What can I do to make the best color? Single-color yellow worth the most. If you put too much together, the color would get darker and darker. The darker it gets, the value of it goes down as well. This is the hardest part. If you use fine materials, it is natural for you to make a fine product. How you think out the combination of materials is very important.

Could you tell me about your different works?

Tools

Could you tell me about the tools?

(Left end)Gangi, (On the right)Kisage for finish works and pasting

Could you tell me what the base you are using is called?

Do you have any succeeded tools?

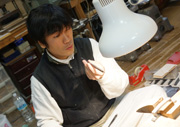

All of these are. There are no particular new tools here. Tortoise shell craftsman also use machines quite a lot, but there are some process where you would have to do by hand. The part where you combine pieces can never be done by machines. This might be one of the reasons why we cannot mass-produce.

It seems that handcraft is essential.

Yes, because I would have to see the color. It might be possible to mechanize if it was just matching the thickness, but human eyes are needed to see if the color is appropriate. I would have to make the materials first myself, so it is very hard to mass-produce. Also, the tools I use are almost completely same as the tools people used in Edo period. When I saw the record from old times, they have pictures of the same tools. A book called “Taimaikame Diagram” has explanations of the tools. To polish, they used to use leaves of mukutree or saliva. Saliva was said to be good because it is alkaline. Tortoiseshell primarily does not have luster. It lusters when it’s wet. With the same logic, you would have to make a thin film on the surface. To make this film, polishing is done.

Pride as a craftsman

What makes this job a worthwhile one?

They used to have division of labor in tortoise shell work, but now, the work is done alone from the start to finish. This part makes my job fulfilling. It surely takes an enormous effort, but with materials, you can start from zero to finishing the piece.

I guess this is not the only reason but because of the Washington Convention, there are very few people who become tortoise shell craftsman. I was grown and lived by it so I am wishing that this would never come to an end.

Could you tell me about your feelings for tortoise shell.

Akira Akatsuka

Other than eyeglasses, we also make accessaries.

Studio

About Taimai (hawksbill turtle)

After importing taimai, which is the material for tortoise shell, was banned due to the Washington Convention, all the tortoise shell craftsmen have to supply the materials for themselves. Taimai used for these ornaments are the ones with low quality.

Tortoise shell in Edo Period

A ko-gai and a comb decorated in the store are made during the Edo period.

Materials such as an elephant tusk never deteriorate and it even gets its luster as they are used. Also, the name of the craver would worth with the name carved on the product. On the other hand, works of tortoise shell basically do not have their artist. Tortoise shell is at its best quality when its first made into a product and after, it only deteriorates. This is thought to be one of the good things about tortoise shells.